徐文生 研究员

文章来源: 发布时间:2020-07-07

|

徐文生 研究员 |

| 高分子化学与物理 | |

| 网络与计算中心207室 | |

| 电话:0431-85262480 | |

| Email:wsxu@ciac.ac.cn | |

| 个人主页:glass-ciac.com |

| 教育和工作经历 |

| 教育经历 2007.09—2012.07 中国科学院长春应用化学研究所,高分子化学与物理,博士 (导师:安立佳院士 孙昭艳研究员) 2003.09—2007.07 天津大学,材料科学与工程,本科 工作经历 2019.01—至今 中国科学院长春应用化学研究所,高分子物理与化学国家重点实验室,研究员 2018.10—2019.01 中国科学院长春应用化学研究所,高分子物理与化学国家重点实验室,项目聘用(导师:安立佳院士) 2016.08—2018.09 美国橡树岭国家实验室,纳米相材料科学中心,博士后(导师:Dr. Yangyang Wang) 2013.01—2016.07 美国芝加哥大学,James Franck研究所,博士后(导师:Prof. Karl F. Freed) 2007.08—2013.01 中国科学院长春应用化学研究所,高分子物理与化学国家重点实验室,项目聘用(导师:安立佳院士) |

| 学术兼职 |

| 主要荣誉 |

| 2018年 美国橡树岭国家实验室纳米相材料科学中心杰出科学论文奖 |

| 研究兴趣 |

| 1.高分子流变学;2.高分子玻璃化 |

| 研究资助 |

| 国家自然科学基金面上项目、中国科学院长春应用化学研究所启动基金、美国橡树岭国家实验室纳米相材料科学中心用户项目 |

| 研究领域和现状 |

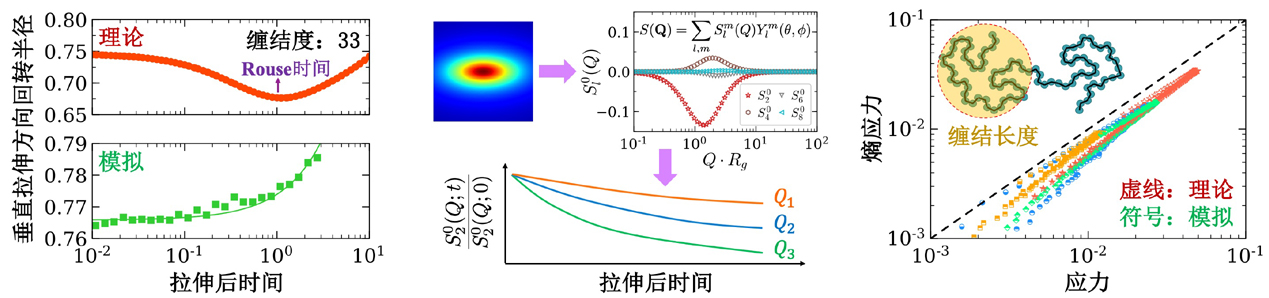

| 高分子流变学是发展高分子材料加工成型技术的学科基础,其核心任务是建立高分子在流场下的结构变化和力学响应的对应关系;高分子玻璃化决定了材料的加工和应用温度范围,其核心任务是揭示高分子玻璃形成的物理机制进而为其分子设计提供指导。本研究组围绕上述核心任务,针对缠结高分子非线性流变行为的分子机理以及单体结构影响高分子玻璃化的热力学成因和微观机理等问题开展理论模拟研究工作。 1.缠结高分子非线性流变行为的分子机理 缠结高分子的非线性流变行为是高分子流变学的核心科学问题之一,其当前的理论解释主要基于四十多年前de Gennes、Edwards和Doi开创的经典管子模型。由于管子模型能够成功地描述缠结高分子的平衡态和近平衡态性质,该模型被认为是当代软物质物理中最成功的理论之一,并且作为标准知识出现在多数高分子物理和流变学教科书中。对缠结高分子在快速大形变条件下的非线性流变行为,认清其微观物理图像不仅是当前研究中的前沿和难点所在,更是建立缠结高分子本构方程的关键所在。管子模型设想形变后高分子链的轮廓长度松弛和取向松弛解耦合,称为链回缩假设。我们的模拟结果表明链回缩并未发生,从分子尺度阐明了大形变后缠结高分子构象松弛的物理图像。更进一步,我们提出利用球谐展开方法表征各向异性的高分子构象,即将一个二维物理量分解为一系列展开系数和球谐函数的乘积。在此方法基础上,我们从不同时空研究了高分子构象在等轴拉伸后的松弛行为,并且提出了一种基于Rouse变量的新机理。我们的模拟结果还指出缠结尺度上的链内熵应力显著低于应力,表明链间构型熵对应力也有所贡献。这与管子模型设想应力完全源于缠结尺度上链内构型熵变化的设想不同,由此明晰了形变高分子应力的微观根源这一问题。

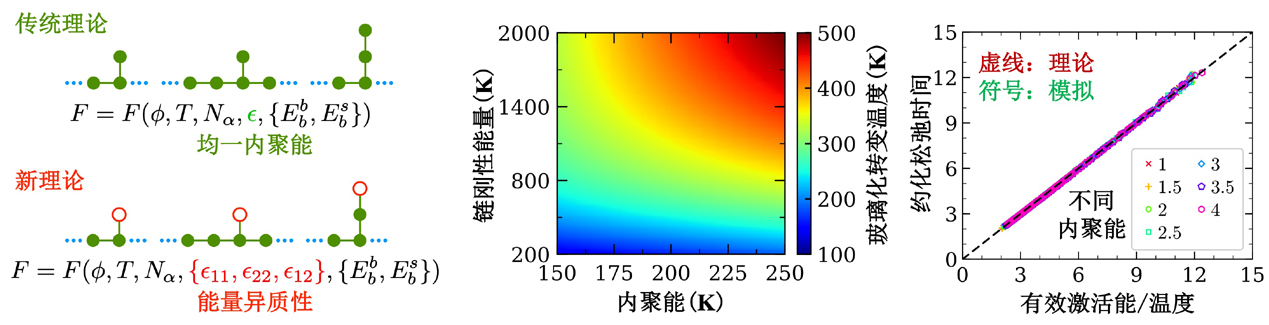

2.单体结构影响高分子玻璃化的理论和模拟研究 高分子的长链结构和复杂单体结构特征是高分子玻璃具有独特物理性质和先进功能的分子根源。传统的Flory-Huggins理论和Gibbs-DiMarzio理论忽略了单体分子结构对高分子热力学性质的影响,无法预测由单体结构差异造成的高分子玻璃化行为的变化。虽然Freed的格子集团理论包含了单体结构这一分子特征,但是该理论采用了将构成单体的所有基团均视为等同的简化处理。高分子单体中常含有不同种类的基团,而不同种基团间的内聚能差别显著,所以建立高分子玻璃化定量理论的一个关键问题是能否将这种能量异质性包含到理论模型当中,进而对高分子玻璃化的转变温度和脆性指数进行准确预测,最终指导高分子材料的加工成型和应用。我们围绕高分子玻璃化中的这个关键问题,建立了适宜的理论和模拟分析方法,系统研究了玻璃质高分子熔体的热力学、结构和动力学性质,明晰了单体结构影响高分子玻璃化特征性质的热力学成因和微观机理。我们在格子集团理论基础上区分单体内的基团种类,通过扩展统计力学中的Mayer集团展开技术并且解决经典Adam-Gibbs熵理论中的问题,建立了能够描述单体能量异质性的高分子玻璃化热力学理论,揭示了单体结构差异导致的构型熵变化是单体结构影响高分子玻璃化的热力学成因。同时,我们采用类串协同运动分析与分子动力学模拟相结合的方法,详细考察了内聚能和压力等因素对高分子玻璃化的影响,从分子尺度确立了类串协同运动在高分子玻璃化中的重要角色,明晰了单体结构影响高分子玻璃化的微观机理。

|

| 主要代表性论文 |

| 2020 1. Wen-Sheng Xu*, Jack F. Douglas*, and Xiaolei Xu*, “Molecular Dynamics Study of Glass Formation in Polymer Melts with Varying Chain Stiffness,” Macromolecules 2020, 53, 4796–4809. 2. Wen-Sheng Xu and Wenjie Xia*, “Energy Renormalization for Coarse-Graining Polymers with Different Fragilities: Predictions from the Generalized Entropy Theory,” Macromolecular Theory and Simulations 2020, 29, 1900051. 2019 3. Xinyi Wang, Wen-Sheng Xu, Hao Zhang*, and Jack F. Douglas*, “Universal nature of dynamic heterogeneity in glass-forming liquids: A comparative study of metallic and polymeric glass-forming liquids,” The Journal of Chemical Physics 2019, 151, 184503. 4. Wenjie Xia*, Nitin K. Hansoge, Wen-Sheng Xu, Frederick R. Phelan Jr., Sinan Keten*, and Jack F. Douglas*, “Energy renormalization for coarse-graining polymers having different segmental structures,” Science Advances 2019, 5, eaav4683. 5. Wen-Sheng Xu, Christopher N. Lam, Jan-Michael Y. Carrillo, Bobby G. Sumpter, and Yangyang Wang*, “Comment on “Relating Chain Conformations to Extensional Stress in Entangled Polymer Melts”,” Physical Review Letters 2019, 122, 059803. 2018 6. Christopher N. Lam#, Wen-Sheng Xu#, Wei-Ren Chen, Zhe Wang, Christopher B. Stanley, Jan-Michael Y. Carrillo, David Uhrig, Weiyu Wang, Kunlun Hong, Yun Liu, Lionel Porcar, Changwoo Do, Gregory S. Smith, Bobby G. Sumpter, and Yangyang Wang*, “Scaling Behavior of Anisotropy Relaxation in Deformed Polymers,” Physical Review Letters 2018, 121, 117801.(共同一作) 7. Wen-Sheng Xu, Jan-Michael Y. Carrillo, Christopher N. Lam, Bobby G. Sumpter, and Yangyang Wang*, “Molecular Dynamics Investigation of the Relaxation Mechanism of Entangled Polymers after a Large Step Deformation,” ACS Macro Letters 2018, 7, 190–195. 2017 8. Wen-Sheng Xu*, Jack F. Douglas*, and Karl F. Freed*, “Influence of Pressure on Glass Formation in a Simulated Polymer Melt,” Macromolecules 2017, 50, 2585–2598. 9. Xiaozheng Duan, Ran Zhang, Mingming Ding*, Qingrong Huang, Wen-Sheng Xu*, Tongfei Shi*, and Lijia An, “Adsorption of a Hydrophobic Cationic Polypeptide onto Acidic Lipid Membrane,” Polymer 2017, 122, 125–138. 10. Xiaozheng Duan, Yang Zhang, Liangyi Li, Ran Zhang, Mingming Ding*, Qingrong Huang, Wen-Sheng Xu*, Tongfei Shi*, and Lijia An, “Effects of Concentration and Ionization Degree of Anchoring Cationic Polymers on Lateral Heterogeneity of Anionic Lipid Monolayers,” The Journal of Physical Chemistry B 2017, 121, 984–994. 2016 11. Wen-Sheng Xu*, Jack F. Douglas*, and Karl F. Freed*, “Generalized entropy theory of glass-formation in fully flexible polymer melts,” The Journal of Chemical Physics 2016, 145, 234509. 12. Wen-Sheng Xu*, Jack F. Douglas*, and Karl F. Freed*, “Stringlike Cooperative Motion Explains the Influence of Pressure on Relaxation in a Model Glass-forming Polymer Melt,” ACS Macro Letters 2016, 5, 1375–1380. 13. Wen-Sheng Xu, Jack F. Douglas, and Karl F. Freed, “Entropy Theory of Polymer Glass Formation in Variable Spatial Dimension,” Advances in Chemical Physics 2016, 161, 443–497. 14. Wen-Sheng Xu*, Jack F. Douglas*, and Karl F. Freed*, “Influence of Cohesive Energy on Relaxation in a Model Glass-Forming Polymer Melt,” Macromolecules 2016, 49, 8355–8370 (2016). 15. Wen-Sheng Xu*, Jack F. Douglas*, and Karl F. Freed*, “Influence of Cohesive Energy on the Thermodynamic Properties of a Model Glass-Forming Polymer Melt,” Macromolecules 2016, 49, 8341–8354. 16. Xiaozheng Duan, Ran Zhang, Yang Zhang, Mingming Ding*, Tongfei Shi*, Lijia An, Qingrong Huang, and Wen-Sheng Xu*, “Monte Carlo study on a complex of cationic polymers and anionic lipid monolayer,” Polymer 2016, 104, 138–148. 17. Xiaozheng Duan, Yang Zhang, Ran Zhang, Mingming Ding*, Tongfei Shi*, Lijia An, Qingrong Huang, and Wen-Sheng Xu*, “Spatial Rearrangement and Mobility Heterogeneity of an Anionic Lipid Monolayer Induced by the Anchoring of Cationic Semiflexible Polymer Chains,” Polymers 2016, 8, 235. 18. Wen-Sheng Xu* and Karl F. Freed*, “Self-assembly and glass-formation in a lattice model of linear telechelic polymer melts: Influence of stiffness of the sticky bonds,” The Journal of Chemical Physics 2016, 144, 214903. 2015 19. Wen-Sheng Xu* and Karl F. Freed*, “Lattice model of linear telechelic polymer melts. II. Influence of chain stiffness on basic thermodynamic properties,” The Journal of Chemical Physics 2015, 143, 024902. 20. Wen-Sheng Xu* and Karl F. Freed*, “Lattice model of linear telechelic polymer melts. I. Inclusion of chain semiflexibility in the lattice cluster theory,” The Journal of Chemical Physics 2015, 143, 024901. 21. Wen-Sheng Xu*, Xiaozheng Duan*, Zhao-Yan Sun*, and Li-Jia An*, “Glass formation in a mixture of hard disks and hard ellipses,” The Journal of Chemical Physics 2015, 142, 224506. 22. Xiaozheng Duan, Mingming Ding, Ran Zhang, Liangyi Li, Tongfei Shi*, Lijia An, Qingrong Huang, and Wen-Sheng Xu*, “Effects of Chain Rigidity on the Adsorption of a Polyelectrolyte Chain on Mixed Lipid Monolayer: A Monte Carlo Study,” The Journal of Physical Chemistry B 2015, 119, 6041–6049. 23. Wen-Sheng Xu* and Karl F. Freed, “Generalized Entropy Theory of Glass Formation in Polymer Melts with Specific Interactions,” Macromolecules 2015, 48, 2333–2343. 24. Wen-Sheng Xu*, Zhao-Yan Sun*, and Li-Jia An*, “Relaxation dynamics in a binary hard-ellipse liquid,” Soft Matter 2015, 11, 627–634. 2014 25. Wen-Sheng Xu* and Karl F. Freed*, “Influence of Cohesive Energy and Chain Stiffness on Polymer Glass Formation,” Macromolecules 2014, 47, 6990–6997. 26. Wen-Sheng Xu* and Karl F. Freed*, “Lattice cluster theory for polymer melts with specific interactions,” The Journal of Chemical Physics 2014, 141, 044909. 27. Yan-Wei Li, Wen-Sheng Xu, and Zhao-Yan Sun*, “Growing point-to-set length scales in Lennard-Jones glass-forming liquids,” The Journal of Chemical Physics 2014, 140, 124502. 2013 28. Wen-Sheng Xu, Yan-Wei Li, Zhao-Yan Sun*, and Li-Jia An*, “Hard ellipses: Equation of state, structure, and self-diffusion,” The Journal of Chemical Physics 2013, 139, 024501. 29. Wen-Sheng Xu and Karl F. Freed*, “Thermodynamic scaling of dynamics in polymer melts: Predictions from the generalized entropy theory,” The Journal of Chemical Physics 2013, 138, 234501. 2012 30. Wen-Sheng Xu, Zhao-Yan Sun*, and Li-Jia An*, “Effect of attractions on correlation length scales in a glass-forming liquid,” Physical Review E 2012, 86, 041506. 31. Wen-Sheng Xu, Zhao-Yan Sun*, and Li-Jia An, “Structure, compressibility factor and dynamics of highly size-asymmetric binary hard-disk mixtures,” The Journal of Chemical Physics 2012, 137, 104509. 32. Wen-Sheng Xu, Zhao-Yan Sun*, and Li-Jia An*, “Dynamics and correlation length scales of a glass-forming liquid in quiescent and sheared conditions,” Journal of Physics: Condensed Matter 2012, 24, 325101. 33. Wen-Sheng Xu, Zhao-Yan Sun*, and Li-Jia An, “Diffusive redistribution of small spheres in crystallization of highly asymmetric binary hard sphere mixtures,” EPL 2012, 97, 66007. 2011 34. Wen-Sheng Xu, Zhao-Yan Sun*, and Li-Jia An*, “Assembly of body-centered cubic crystals in hard spheres,” The European Physical Journal E 2011, 34, 47. 2010 35. Wen-Sheng Xu, Zhao-Yan Sun*, and Li-Jia An*, “Dense packing in the monodisperse hard-sphere system: A numerical study,” The European Physical Journal E 2010, 31, 377–382. 36. Wen-Sheng Xu, Zhao-Yan Sun*, and Li-Jia An*, “Heterogeneous crystallization of hard spheres on patterned substrates,” The Journal of Chemical Physics 2010, 132,144506. |

| 成果评述 |

| 发表在ACS Macro Lett., 2018, 7, 190?195的论文获得美国橡树岭国家实验室纳米相材料科学中心杰出科学论文奖,并且被国家实验室超算中心以亮点成果详细报道(报道链接:https://www.olcf.ornl.gov/2018/04/16/a-problem-with-polymer-theory/)。发表在J. Chem. Phys., 2013, 139, 024501和Macromol. Theory Simul., 2020, 29, 1900051的论文入选期刊封面。受邀在全国高分子学术论文报告会和中国化学会年会等会议上做学术报告交流。 |

| 研究组人员概况 |

| 所在课题组为高分子物理与化学国家重点实验室 安立佳院士 课题组。 |